A Strategic Guide to Sourcing Fabrics Wholesale in India for Global Brands

The global fashion landscape is undergoing a seismic shift. Today’s conscious consumers are no longer satisfied with just "pretty" garments; they demand transparency, ethical production, and environmental responsibility. For global brands and independent designers alike, this shift has turned the spotlight toward India, a land with a textile heritage spanning five millennia. However, navigating the landscape of fabrics wholesale in India is more than just a transaction but a strategic partnership that requires a deep understanding of regional specialties, production cycles and ethical standards.

India offers an unparalleled variety of textiles, from the rugged charm of hand-spun Khadi to the ethereal drape of Mulberry silk. Yet, for a brand based in New York, London, or Paris, the process of fabric sourcing in India can feel daunting. How do you bridge the gap between a high-street design studio and a rural artisan cluster in West Bengal? How do you ensure that your "sustainable" claim is backed by authentic practice? This guide serves as a comprehensive roadmap for global brands looking to integrate the richness of Indian craftsmanship into their collections while maintaining a robust, scalable and ethical supply chain.

Navigating the Market for Fabrics Wholesale in India

When most buyers think of fabrics wholesale, they envision massive industrial warehouses and automated power looms. While India certainly has a massive mill sector, its true competitive advantage for premium and sustainable brands lies in its decentralized sector—the handloom and handicraft clusters.

To source effectively, one must understand that "wholesale" in the Indian context can mean two very different things. First, there is the commodity market, focused on high-volume, low-cost synthetic or mass-produced cotton blends. Second, there is the value-added artisanal market, where "wholesale" refers to bulk orders of hand-crafted textiles. For a brand positioning itself in the sustainable luxury or slow fashion space, the latter is where the magic happens.

Understanding Regional Specializations

India’s textile map is diverse. If you are looking for fine muslins and intricate Jamdani, East India is your destination. For heavy silks and temple weaves, the South beckons. For block prints and natural dyes, the West is king. Understanding these geographic nuances is the first step in successful fabric sourcing in India. By sourcing closer to the origin of the craft, you reduce middleman costs and ensure more of the value reaches the actual makers.

Expert Tip: Don't just look for a "vendor." Look for a sourcing partner who understands both the limitations of artisanal production and the quality requirements of global retail. This bridge is essential for managing expectations regarding lead times and minor "human" variations in handwoven cloth.

For those just starting their journey, understanding the logistics of bulk buying is crucial. You can explore more on this in our guide to smart sourcing and buying wholesale fabrics for your brand.

Identifying and Partnering with Sustainable Fabric Suppliers

Sustainability is no longer a buzzword; it is a prerequisite for market entry in many regions. When evaluating sustainable fabric suppliers, global brands must look beyond the "Eco" label. In India, sustainability is often inherent in traditional methods, but it must be verified through modern standards.

The Pillars of Sustainable Sourcing

- Fiber Origin: Are you sourcing organic cotton, recycled fibers, or "peace" silk (Ahimsa silk)?

- Dyeing Processes: Are the suppliers using GOTS-certified low-impact dyes or natural vegetable dyes?

- Water Management: How is effluent treated? Traditional hand-dyeing often uses less water than industrial processes, but waste management is still vital.

- Social Impact: Does the supplier provide fair wages and safe working conditions? This is the "Ethical" half of sustainability.

Partnering with sustainable fabric suppliers like Anuprerna ensures that these pillars are respected. By focusing on hand-loomed textiles, brands can significantly reduce their environmental impact. Unlike power looms, handlooms require zero electricity, making the fabric's carbon footprint remarkably low. To understand the deeper impact of your choices, read about how to reduce your daily impact with sustainable fabrics.

The Strategic Value of Artisanal Textile Sourcing

For a global brand, artisanal textile sourcing offers something that mass production cannot: a story. In a crowded marketplace, the "story of the maker" is a powerful differentiator. When you source hand-blocked Batik or hand-spun Khadi, you are not just buying yardage, you are investing in a heritage.

Why Artisanal?

- Uniqueness: No two meters of hand-printed or handwoven fabric are identical. This "perfect imperfection" is a hallmark of luxury.

- Low MOQs: Artisanal clusters are often more willing to work with lower Minimum Order Quantities (MOQs) compared to massive mills, allowing smaller brands to test the market without heavy inventory risk.

- Cultural Richness: Incorporating traditional Indian clothing fabrics adds a layer of depth and authenticity to modern silhouettes.

Integrating Artisanal Fabrics into Modern Collections

The challenge for global brands is often translating traditional crafts into contemporary designs. This is where fabric sourcing in India becomes a collaborative design process. For instance, using traditional Batik techniques on modern linen or organic cotton can create a fusion that appeals to global sensibilities while preserving ancient techniques. Explore the living art of Batik fabrics to see how this tradition thrives today.

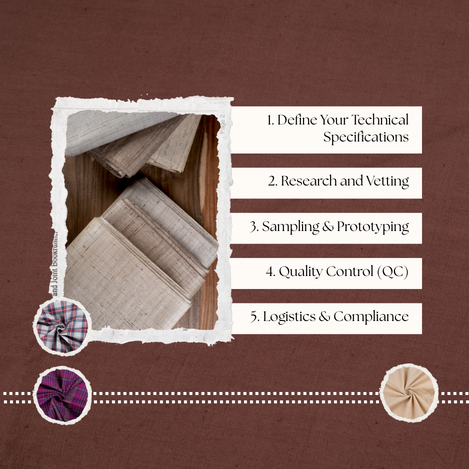

Step-by-Step Guide to Fabric Sourcing in India

To ensure a smooth sourcing experience, follow this structured approach:

1. Define Your Technical Specifications

Before contacting sustainable fabric suppliers, have a clear spec sheet. This should include:

- Fiber composition (e.g., 100% Organic Cotton, 50/50 Silk-Linen blend)

- Fabric weight (GSM)

- Weave type (Twill, Plain, Jamdani)

- Width requirements (Handlooms are often narrower, typically 36" to 45")

2. Research and Vetting

Don't settle for the first supplier you find on a B2B directory. Look for suppliers who have experience with international exports and understand global quality standards (AQL). Check for certifications like GOTS (Global Organic Textile Standard) or Fair Trade. For a deeper dive into the nuances of the Indian market, refer to our guide on sourcing natural textiles in India.

3. Sampling and Prototyping

Always request "yardage samples" before committing to a bulk order. This allows you to test the drape, shrinkage, and colorfastness. In artisanal textile sourcing, expect "strike-offs" for prints or weaves to take 2-4 weeks.

4. Quality Control (QC)

In the world of fabrics wholesale, especially with handmade goods, QC is non-negotiable. If you cannot visit the site, hire a third-party inspection agency or work with a trusted partner like Anuprerna who maintains rigorous in-house quality checks at every stage from yarn spinning to final finishing.

5. Logistics and Compliance

Ensure your supplier is well-versed in export documentation, including the Certificate of Origin, Commercial Invoice, and Packing List. Understand the shipping terms (Incoterms) like FOB (Free on Board) or CIF (Cost, Insurance, and Freight).

Pro Tip: Always factor in the "Monsoon Factor." In India, natural drying processes for hand-printed or dyed fabrics can be delayed during the rainy season (June to September). Plan your production calendars accordingly!

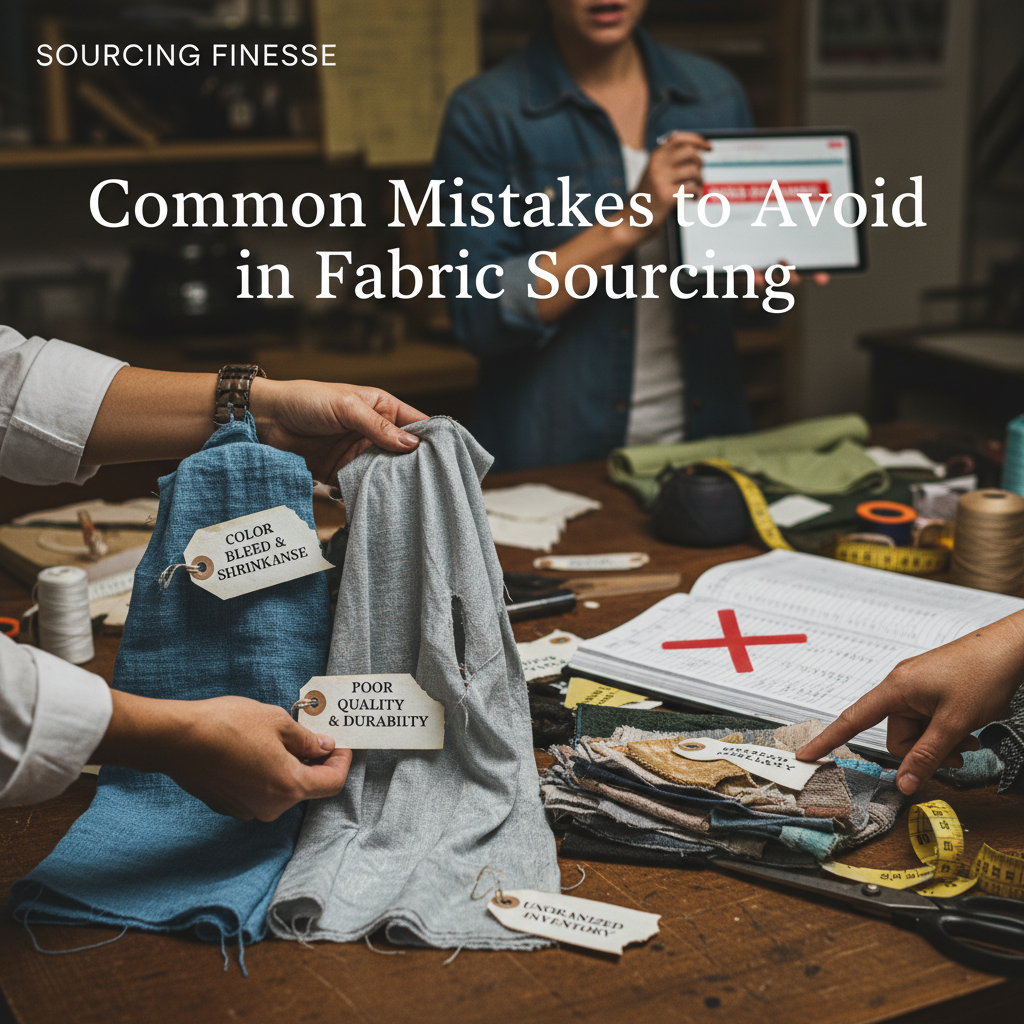

Common Mistakes to Avoid in Fabric Sourcing

- Ignoring Lead Times: Hand-weaving is slow. A 500-meter order of hand-loomed silk cannot be produced in two weeks. Respect the "Slow Fashion" timeline.

- Over-negotiating on Price: When you push for the lowest possible price in fabrics wholesale, the first thing to suffer is often the artisan's wage or the quality of the dye. Fair pricing ensures a sustainable supply chain.

- Assuming Standardization: Hand-crafted fabrics will have slight variations in shade or weave. Educate your customers on why these variations are a sign of authenticity, not a defect.

- Lack of Clear Communication: Use visual aids, pantone shades, and physical swatches. Relying solely on digital images can lead to color discrepancies due to screen calibrations.

Quality, Heritage and Scale in One Supply Chain

Sourcing fabrics wholesale from India offers global brands a unique opportunity to marry high-quality textile production with profound social and environmental impact. By focusing on sustainable fabric suppliers and engaging in meaningful artisanal textile sourcing, brands can move beyond the "fast fashion" cycle and create garments that hold lasting value.

The journey of fabric sourcing in India is one of discovery of finding the right weave, the right artisan cluster, and the right partner who shares your vision for a greener future. As you look to build your next collection, remember that the fabric you choose is the foundation of your brand's story. Choose a fabric that weaves together quality, heritage and ethics.

Ready to start your sourcing journey? Explore Anuprerna’s curated collection of sustainable, handwoven fabrics and connect with our team to bring your designs to life with the touch of Indian craftsmanship.

most asked questions

What are the typical MOQs for ordering fabrics wholesale in India?

arrow_drop_downMinimum Order Quantities (MOQs) vary significantly depending on the production method. For industrial mill-made fabrics, MOQs can be as high as 1,000 to 3,000 meters. However, when working with sustainable fabric suppliers focusing on handloom textiles, MOQs are much more flexible, often starting as low as 30 to 50 meters per color or design. This makes India an ideal hub for boutique brands and designers who prioritize exclusivity over mass volume.

How do I verify if a fabric supplier is truly sustainable?

arrow_drop_downVerification requires a multi-pronged approach. Look for international certifications such as GOTS (for organic fibers), OEKO-TEX (for chemical safety), or Fair Trade. Beyond certifications, ask for transparency regarding their supply chain. A legitimate sustainable fabric supplier should be able to tell you where the yarn was spun, who did the weaving, and how the waste from the dyeing process was managed. Physical or virtual site visits are also highly recommended.

Why is artisanal textile sourcing more expensive than mill-made fabrics?

arrow_drop_downArtisanal textile sourcing involves a high degree of manual labor, specialized skills passed down through generations, and often, slower production rates. Unlike power looms that can produce hundreds of meters a day, a handloom weaver might only produce 2-4 meters of intricate fabric daily. The price reflects the fair wages paid to skilled artisans, the use of high-quality natural fibers, and the low-impact environmental footprint of the production process.

How long does the fabric sourcing process in India usually take?

arrow_drop_downFor stock fabrics, sourcing can take 1-2 weeks for shipping. However, for custom-developed fabrics wholesale, the timeline is usually 6 to 12 weeks. This includes the time for yarn preparation, dyeing, loom setup, weaving, and quality finishing. It is essential for global brands to align their design calendars with these traditional production cycles, especially when factoring in international shipping and customs clearance.

Can I get custom prints or weaves developed in India?

arrow_drop_downYes, India is one of the best places for custom textile development. Whether it is a specific Ikat pattern, a unique Jamdani motif, or a custom block print, sustainable fabric suppliers in India excel at bespoke creations. To start this process, you typically provide a digital design or a physical swatch, and the artisans create a "strike-off" for your approval before proceeding with bulk production.

More Blogs

ethical supply chains: the sustainability impact of khaadi online shopping

performance metrics: analyzing banana fiber fabric properties for textile design

the scrap fabric solution, from clutter to creation

the art of sustainable recyclability

indian handloom in contemporary world

sustainability through handloom manufacturing