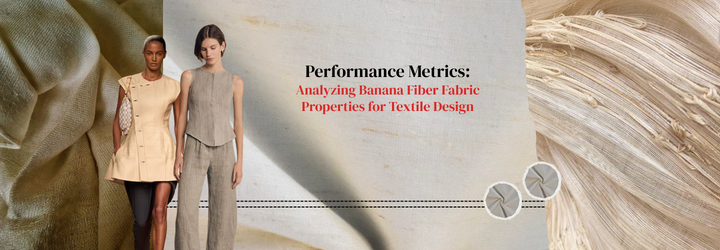

Performance Metrics: Analyzing Banana Fiber Fabric Properties for Textile Design

As sustainable fashion matures, designers and B2B buyers are no longer impressed by labels alone. Materials now have to perform. While organic cotton and linen still dominate the eco conversation, a quieter, more technical contender is gaining ground: banana fiber fabric.

Extracted from the pseudostem of the banana plant, a part traditionally treated as agricultural waste, banana fiber reframes circularity as a functional input, not a marketing claim. At Anuprerna, we see it less as a novelty and more as a material system. Visually, it sits between linen’s rawness and silk’s subtle sheen. Technically, it offers a compelling balance of strength, breathability, and texture.

This analysis breaks down key banana fiber fabric properties, from tensile strength to moisture behavior, and places them directly against organic cotton. The goal is not to crown a winner, but to clarify where each material performs best. Because in serious design, sustainability only matters if the fabric holds up where it counts.

The Technical Breakdown: Banana Fiber Fabric Properties and Performance

To design effectively with any material, one must first understand its DNA. Banana fiber, scientifically known as musaceous fiber, is a lignocellulosic fiber, meaning it is composed of cellulose, hemicellulose, and lignin. This chemical composition is the foundation of its impressive performance metrics.

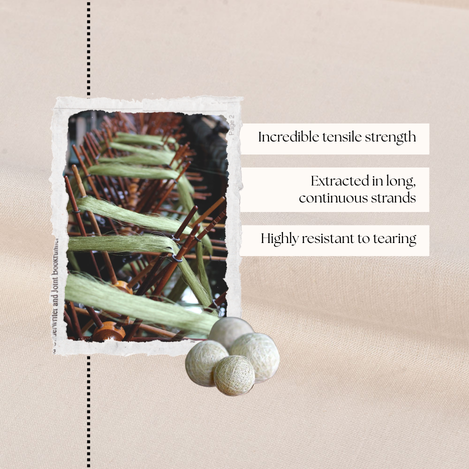

Tensile Strength and Banana Textile Durability

One of the most striking properties of banana fiber is its incredible tensile strength. In fact, it is one of the strongest natural fibers available in the textile industry today. Unlike cotton, which relies on shorter staples, banana fibers can be extracted in long, continuous strands. This structural integrity translates directly into banana textile durability.

For B2B applications, this means the fabric is highly resistant to tearing and can withstand the rigors of industrial garment processing. Whether you are designing structured outerwear or high-use home textiles, banana fiber maintains its shape and strength over time, often outlasting traditional natural fibers.

Moisture Absorption and Breathability

In the context of tropical or summer wear, moisture management is non-negotiable. Banana fiber is highly absorbent; it can wick moisture away from the skin and release it into the atmosphere rapidly. This "breathability" is due to the fiber's porous micro-structure. When compared to synthetic alternatives, banana fiber keeps the wearer significantly cooler, making it an ideal choice for brands targeting conscious consumers in warmer climates.

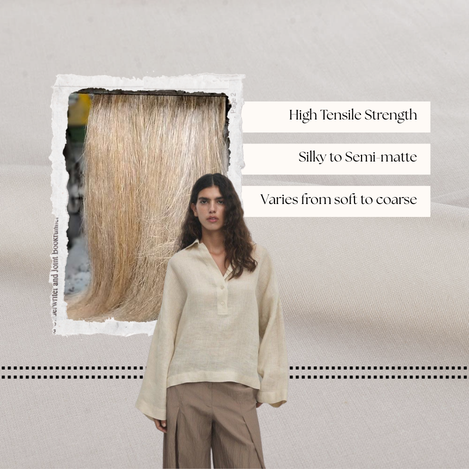

Natural Luster and Dye Affinity

Aesthetically, banana fiber possesses a natural sheen that mimics silk. This makes it a popular choice for luxury sustainable collections. Furthermore, the fiber has a high affinity for dyes. Whether using natural vegetable dyes or low-impact synthetics, the fiber absorbs color deeply and evenly, resulting in rich, vibrant hues that resist fading.

Banana Fiber vs Organic Cotton: A Comparative Analysis for Designers

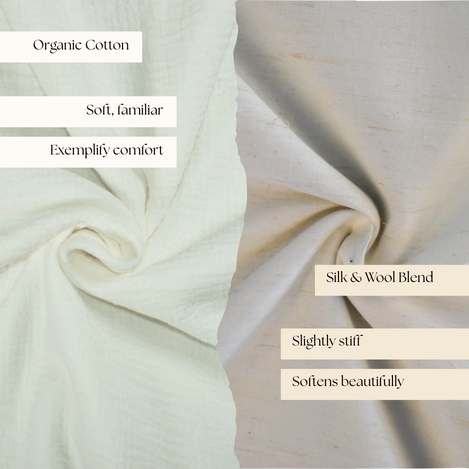

When deciding between banana fiber vs organic cotton, designers must weigh the trade-offs between softness, structure, and environmental footprint. While both are pillars of sustainable manufacturing, they serve different functional purposes.

Softness vs. Structure

Organic cotton is celebrated for its immediate "hand-feel"—it is soft, familiar, and comfortable from the first wear. Products like our Plain White Organic Cotton Double Gauze exemplify this comfort.

Banana fiber, however, offers more "body" and structure. In its pure form, it can be slightly stiff, similar to raw linen or ramie. However, as it is washed and worn, it softens beautifully without losing its structural integrity. For designers looking to create architectural silhouettes or crisp, tailored garments, banana fiber provides a level of definition that organic cotton often lacks.

Environmental Impact and Water Usage

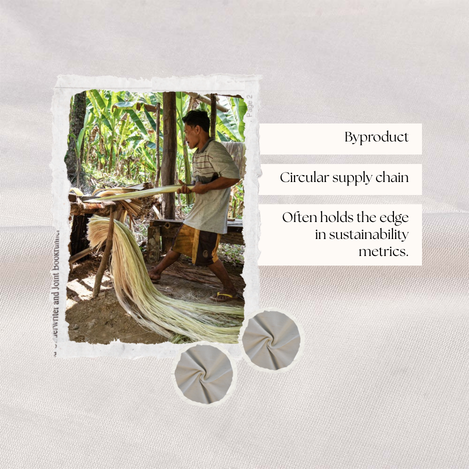

While organic cotton is a massive improvement over conventional cotton, it still requires significant water for cultivation. Banana fiber, conversely, is a byproduct of the food industry. The banana plants are already grown for their fruit; extracting the fiber requires no additional land, very little extra water, and turns "waste" into a high-value textile. For a B2B brand aiming for a truly circular supply chain, banana fiber often holds the edge in sustainability metrics.

Blending Opportunities

At Anuprerna, we often recommend blending these two powerhouse fibers. By combining the softness of Handspun Cotton Khadi with the strength and sheen of banana fiber, we create textiles that offer the best of both worlds: the comfort of cotton and the performance of banana.

Designing with Banana Fiber: From Craftsmanship to Commercial Utility

Textile design sits at the intersection of heritage and technology.

In East India, banana fiber extraction and weaving are embedded in artisan communities, making the material’s journey from fruit to fabric central to its value and narrative.

Weaving Techniques and Patterns

Banana fiber performs well on the loom, supporting intricate textile designs such as stripes, checks, and jacquards. Its slightly thicker structure compared to fine cotton creates a distinct tactile relief in the finished fabric.

For B2B buyers, banana fiber is available in multiple weights. Fine yarns suit lightweight summer dresses, while heavier yarns work well for upholstery and accessories. In yarn-dyed constructions, similar to our Pure Cotton Yarn Dyed Checks, the fabric develops strong visual depth and texture.

Durability in End Use

Banana fiber’s durability makes it well suited for:

- Sustainable luxury apparel: Silk-like sheen with vegan credentials

- Accessories: Bags and hats requiring strength and weather resistance

- Home textiles: Table runners and cushion covers that withstand frequent washing while retaining structure

Sourcing and Ethical Manufacturing: The Anuprerna Approach

For B2B buyers, fabric performance extends beyond material properties to supply-chain reliability. Sourcing from Anuprerna means working within a transparent, ethical ecosystem rooted in East India.

We partner directly with artisan clusters, ensuring the labor-intensive extraction process is fairly compensated. This social sustainability safeguards both fiber quality and artisan livelihoods. Whether it is our Handspun Cotton Khadi 65 GSM or banana fiber blends, each fabric represents a heritage craft refined for modern production.

Consistency is the usual challenge with natural fibers. We address this through controlled processing and quality checks that meet international B2B standards for colorfastness, shrinkage and tensile strength, balancing handloom character with the precision global brands require.

Why Banana Fiber Belongs in the Next Generation of Sustainable Textiles

Analyzing the performance metrics of banana fiber fabric reveals a material that is not only sustainable but technically superior in many categories. From its unmatched banana textile durability to its unique moisture-wicking banana fiber fabric properties, this "waste-to-wealth" material is a cornerstone of future textile design.

When comparing banana fiber vs organic cotton, it is clear that neither is a "replacement" for the other. Instead, they are complementary tools in a designer's kit. By understanding when to leverage the structure of banana and when to lean into the softness of cotton, brands can create collections that are as functional as they are beautiful.

Are you ready to elevate your sustainable collection with the strength and luster of banana fiber? At Anuprerna, we specialize in bringing these artisan-made, high-performance textiles to the global stage.

most asked questions

Is banana fiber fabric itchy or rough on the skin?

arrow_drop_downWhile raw banana fiber has a structural, slightly crisp feel similar to linen, it is not "itchy." When processed correctly and woven with skill, it feels smooth. Furthermore, like all high-quality natural fibers, it softens significantly with each wash. For those seeking maximum softness, we recommend banana-cotton blends, which combine the performance of banana with the familiar comfort of organic cotton.

How does banana textile durability compare to synthetic fibers like polyester?

arrow_drop_downIn terms of tensile strength and resistance to wear, banana fiber is exceptionally durable for a natural material. While synthetics like polyester are engineered for extreme durability, they lack the breathability and biodegradability of banana fiber. For B2B brands, banana fiber offers a high-performance natural alternative that does not contribute to microplastic pollution, making it a superior choice for the circular economy.

Can banana fiber fabric be machine washed?

arrow_drop_downYes, banana fiber fabric is quite resilient. However, to maintain the natural luster and prevent excessive wrinkling, we recommend a gentle machine wash or hand wash with mild detergents. It is best to air dry the fabric in the shade. Because of its high tensile strength, it does not lose its shape easily during the washing process, which is a key advantage for garment longevity.

In the debate of banana fiber vs organic cotton, which is better for the environment?

arrow_drop_downBoth are excellent choices, but they serve different ecological roles. Organic cotton improves upon traditional farming by eliminating toxic pesticides. Banana fiber, however, is a "circular" fiber. It uses the waste from an existing food crop, requiring no new land or additional water for cultivation. If your brand’s priority is zero-waste and circularity, banana fiber is often the more sustainable metric.

Is banana fiber fabric suitable for high-end luxury fashion?

arrow_drop_downAbsolutely. Due to its natural sheen and ability to hold vibrant dyes, banana fiber is often referred to as "vegan silk." It has been used by several luxury houses for its unique texture and drape. It provides a sophisticated, high-end aesthetic that aligns perfectly with the growing demand for luxury materials that are both ethical and animal-free.

More Blogs

the scrap fabric solution, from clutter to creation

the art of sustainable recyclability

indian handloom in contemporary world

sustainability through handloom manufacturing

how to identify handloom fabrics in a powerloom world

ketia silk - a peace lover