About Our Impact

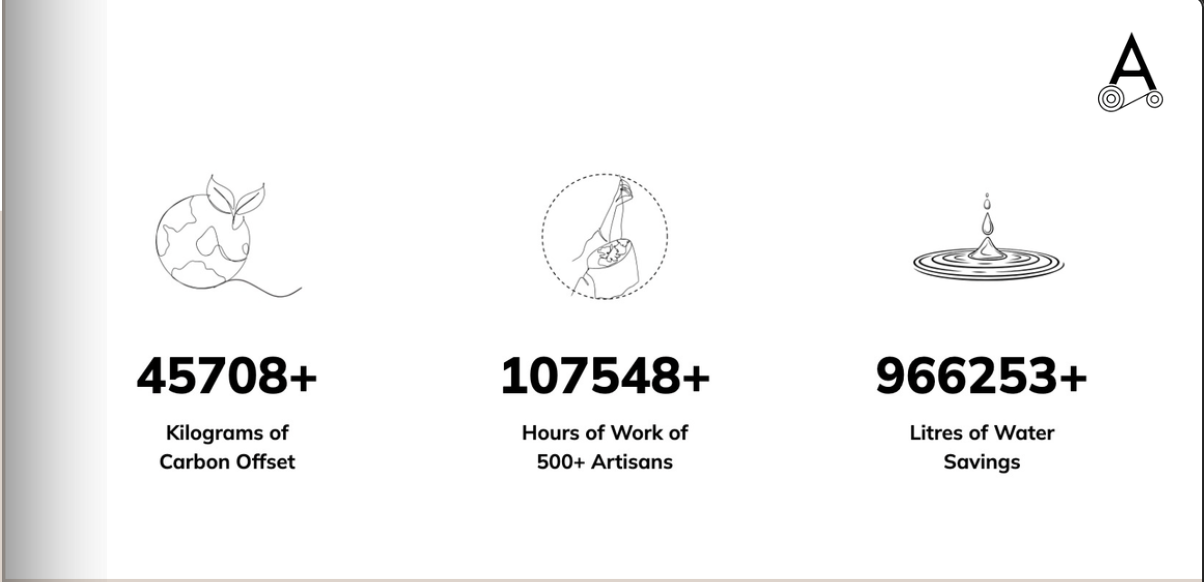

At Anuprerna, our mission is to create a transparent, ethical and eco-friendly ecosystem that benefits people and the planet. Join us on this inspiring journey to build a better, more equitable world for tomorrow. Being An Ethical & Sustainable Textile Manufacturer, One Of Our Primary Objectives Is To Bring Sustainability To Our Artisanal Textiles Production Through A Transparent Supply Chain. Our journey at Anuprerna is rooted in a simple ambition: empowering artisans. Discover more about our 2025 impact, innovation, and initiatives in our Annual Impact Report 2025 here.

INTRODUCTION

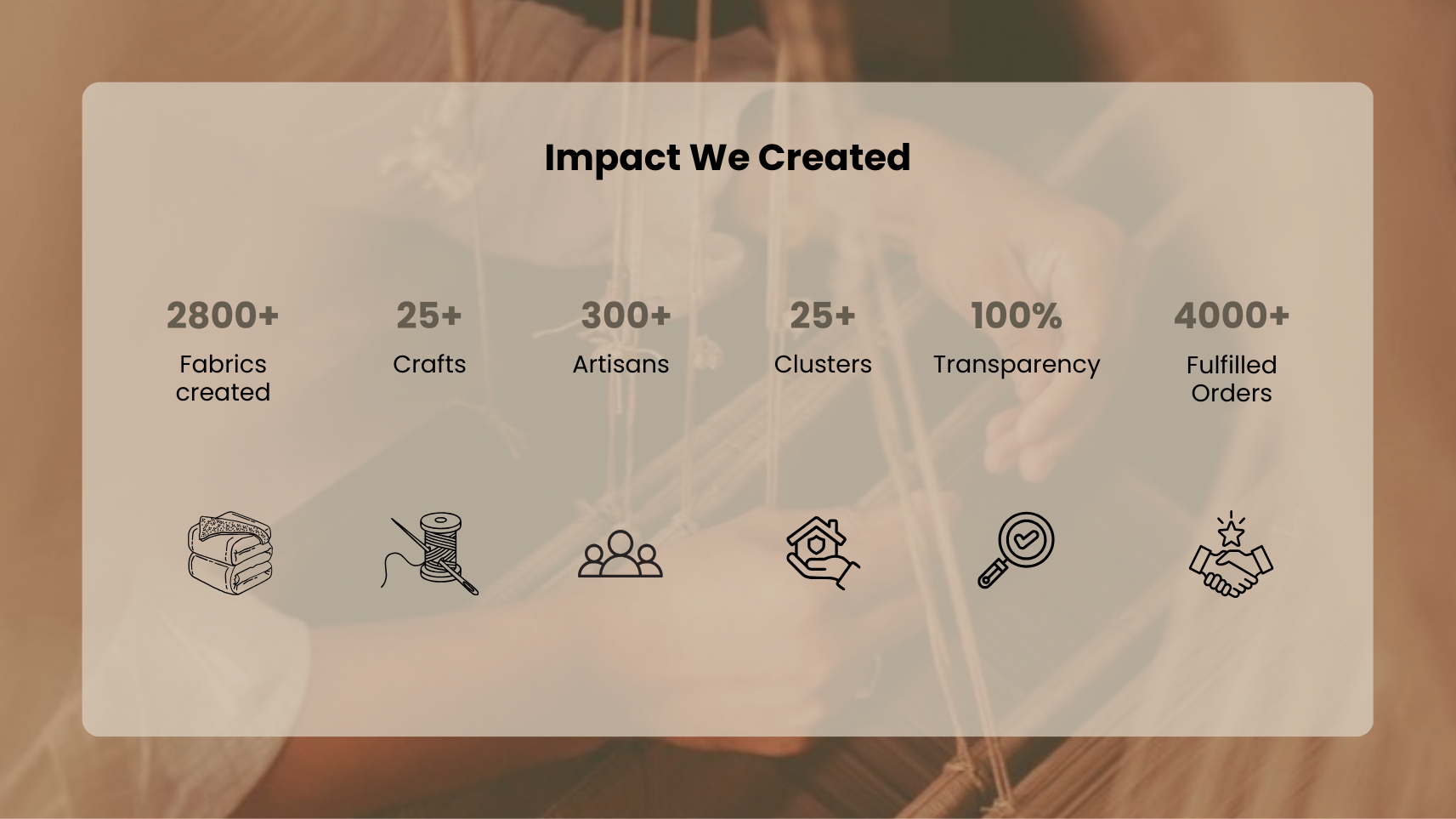

Over the last five years, we’ve collaborated with 500+ artisans across 30 clusters in West Bengal, Odisha, and Assam, impacting 2,000+ lives while preserving 25+ indigenous crafts. Our network comprises 60% male and 40% female artisans, with strong participation of women across spinning, pre-weaving, and weaving. On average, each artisan supports four dependent family members, extending livelihood impact to entire rural households. Through eco-friendly practices and a tech-enabled transparent supply chain, we demonstrate that sustainability and artisanal craftsmanship can co-exist and scale together.

We’ve strengthened decentralized artisanal production with a tailored B2B platform and a tech-enabled supply chain, ensuring transparency and traceability from fiber to finished products.

OUR ARTISAN COMMUNITY IMPACT 2025 HIGHLIGHTS

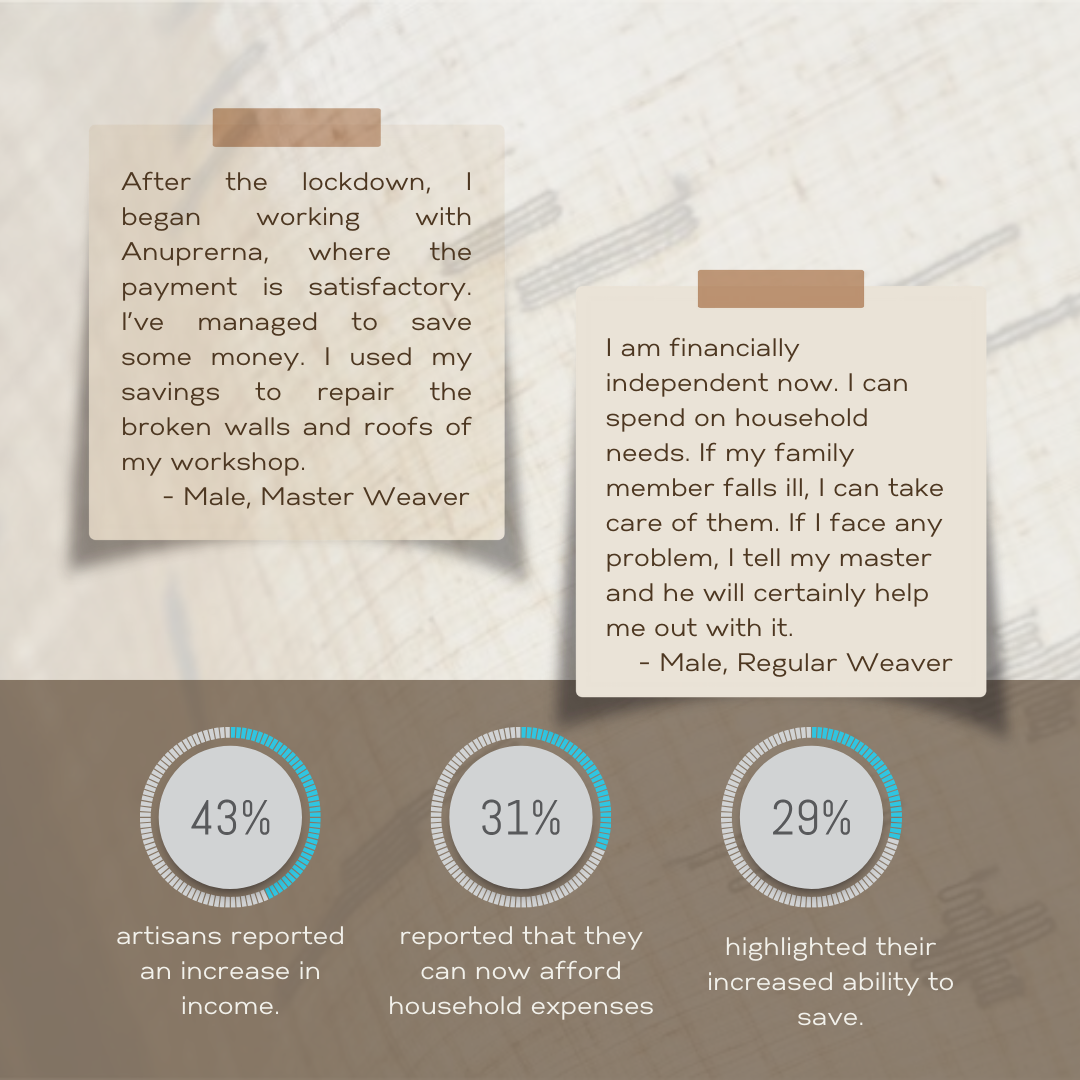

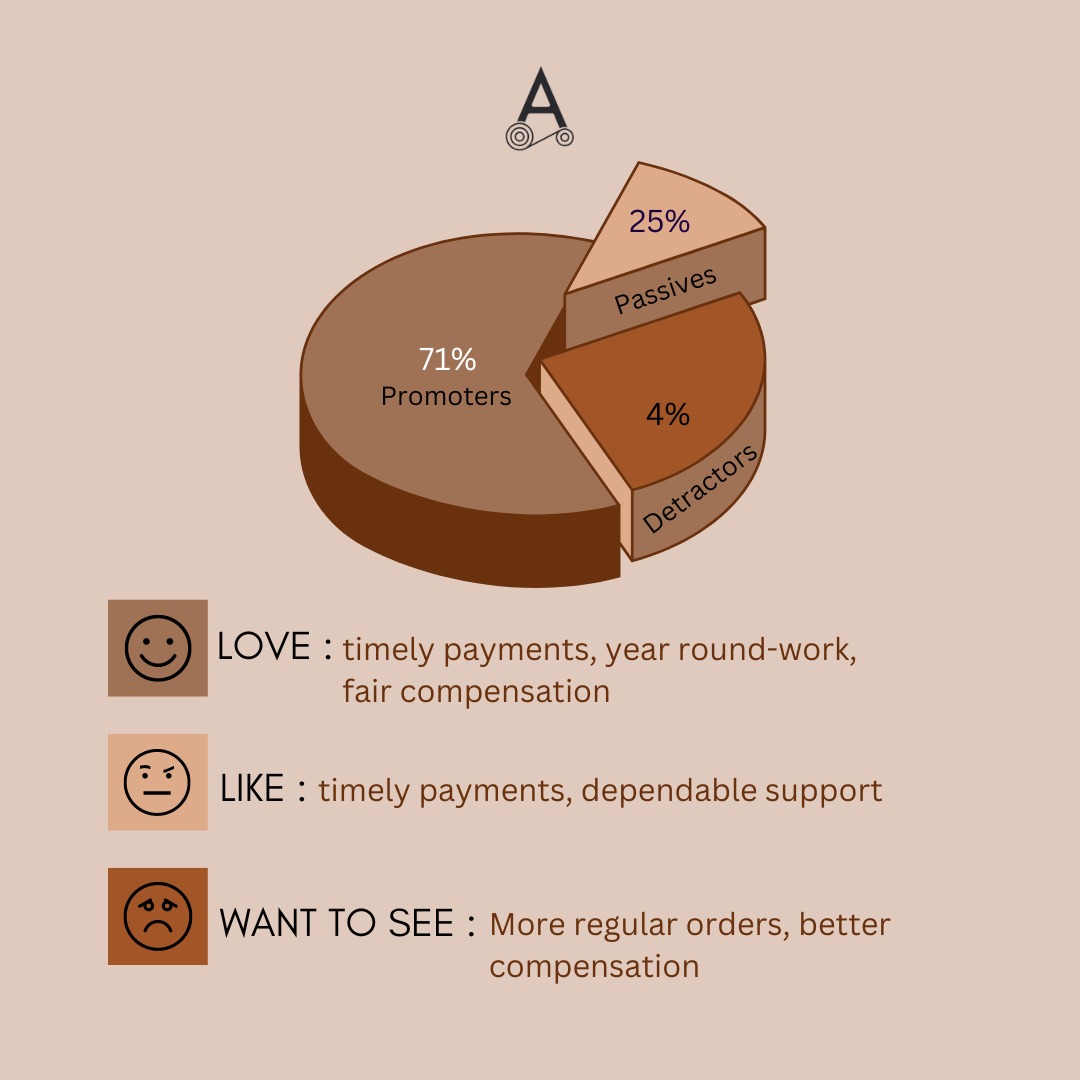

IMPACT REPORT 2025, COLLABORATION WITH 60 DECIBELS

Anuprerna in partnership with 60 Decibels, an independent organization specializing in social impact measurement, has conducted a bottom up impact study via telephonic interviews with 56 weavers to better understand the impact of our skilled weavers and master artisans.Anuprerna’s impact extends beyond financial security—it empowers artisans to improve their quality of life and invest in their future.

TOP INSIGHTS FROM ARTISANS

- Nearly 9 in 10 weavers reported their work has improved while working with Anuprerna

- 7 in 10 weavers have worked with Anuprerna for over 5 years.

46% of weavers involve family members in the craft. - Regular price increases have positively impacted wages.

- Anuprerna provided crucial support during the lockdown, ensuring job security

OUR CONTRIBUTION

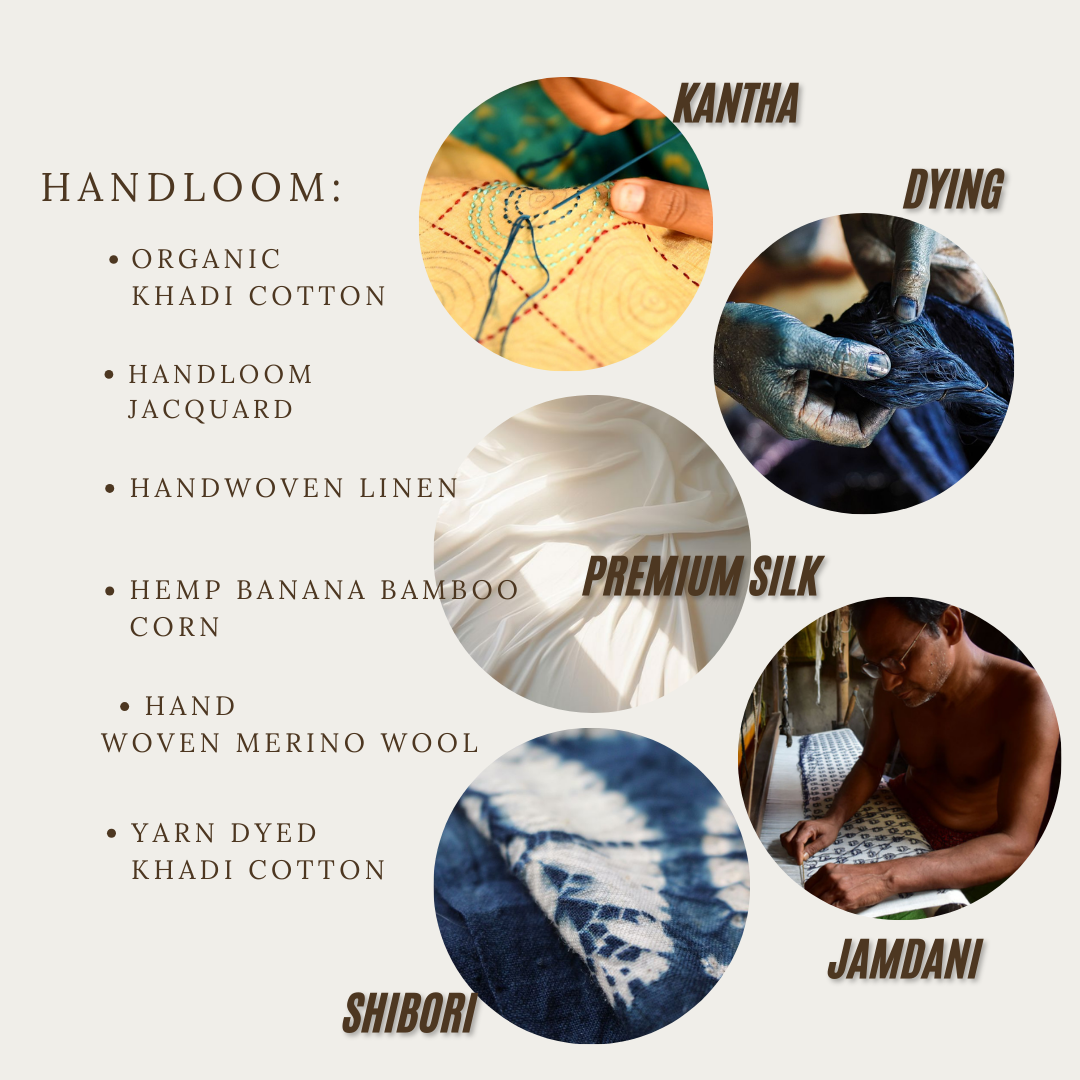

CRAFT AND CLUSTER

Indian craft clusters are vibrant hubs of artisanal skill, preserving ancient traditions. Anuprerna is closely working with Artisans from a cluster located in various parts in West Bengal. These artisans possess specialized skills and knowledge that have been passed down through generations, making their craft a vital part of the cultural fabric of the region.

SUSTAINABILITY OF HANDLOOM

Harnessing the power of traditional craftsmanship, handlooms exhibit an impressive 30% reduction in energy consumption compared to their power loom counterparts. This not only translates into significant cost savings but also plays a vital role in minimizing carbon emissions, contributing to a greener planet. Furthermore, handloom practices demonstrate responsible water usage, conserving this precious resource and significantly reducing pollution. The holistic benefits of handlooms extend far beyond the production of beautiful, bespoke fabrics, making a positive impact on our environment and fostering a sustainable future.

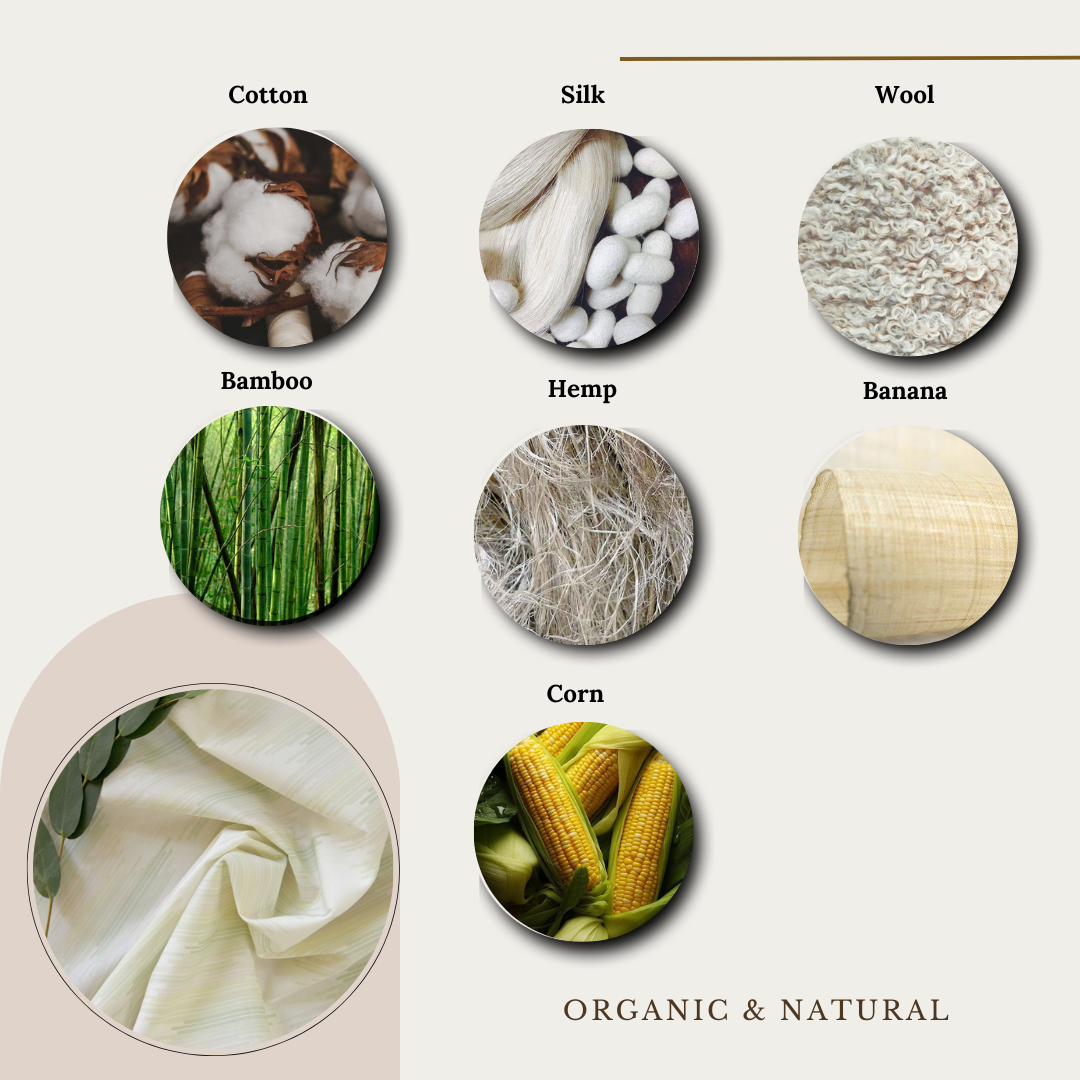

SOURCES OF OUR NATURAL FIBERS

We are also working on an organic Khadi fabric collection, which requires us to source certified organic cotton fibre and then spun and woven into Organic Khadi. So the final texture would be a little different due to the hand process which is what we specialize in.

Regarding the source of fibre, cotton farming primarily happens in South Indian regions. Once the cotton is farmed, they are either mill spun which happens in South & West India but we source primarily from the South. And also these yarns are handspun in many regions on a small to large scale. This handspun yarn is called Khadi which we source from our state and adjacent states in Eastern India where we are located. The handspun nature gives it a non-uniformity therefore high breathability but at the same time inconsistent dying due to unevenness within the yarn. Details on fabric sourcing we have captured here.

OUR IMPACT ACROSS THE VALUE CHAIN

Anuprerna is dedicated to minimizing its environmental impact across the entire value chain. From sampling and production to processing, weaving, quality checking, and packaging, the company employs a range of sustainable practices to reduce its impact on the environment.

Sourcing: We source natural yarns & chemicals from vendors across East & South India. We also work with regional SHGs and spinning clusters to source Handspun Khadi yarns.

Sampling: We ensure that our designing & sampling processes are as sustainable as possible, repurposing rejected fabric, which is also 100% natural, from quality checking to creating prototypes and samples in smaller quantities.

Production: We are committed to sustainable Made-to-order production practices, using solar energy and handlooms that do not require fuel or electricity in all of its production processes. We also offer flexibility in smaller quantities of sampling which further eliminates wastage of resources.

PROCESS THAT INVOLVES:

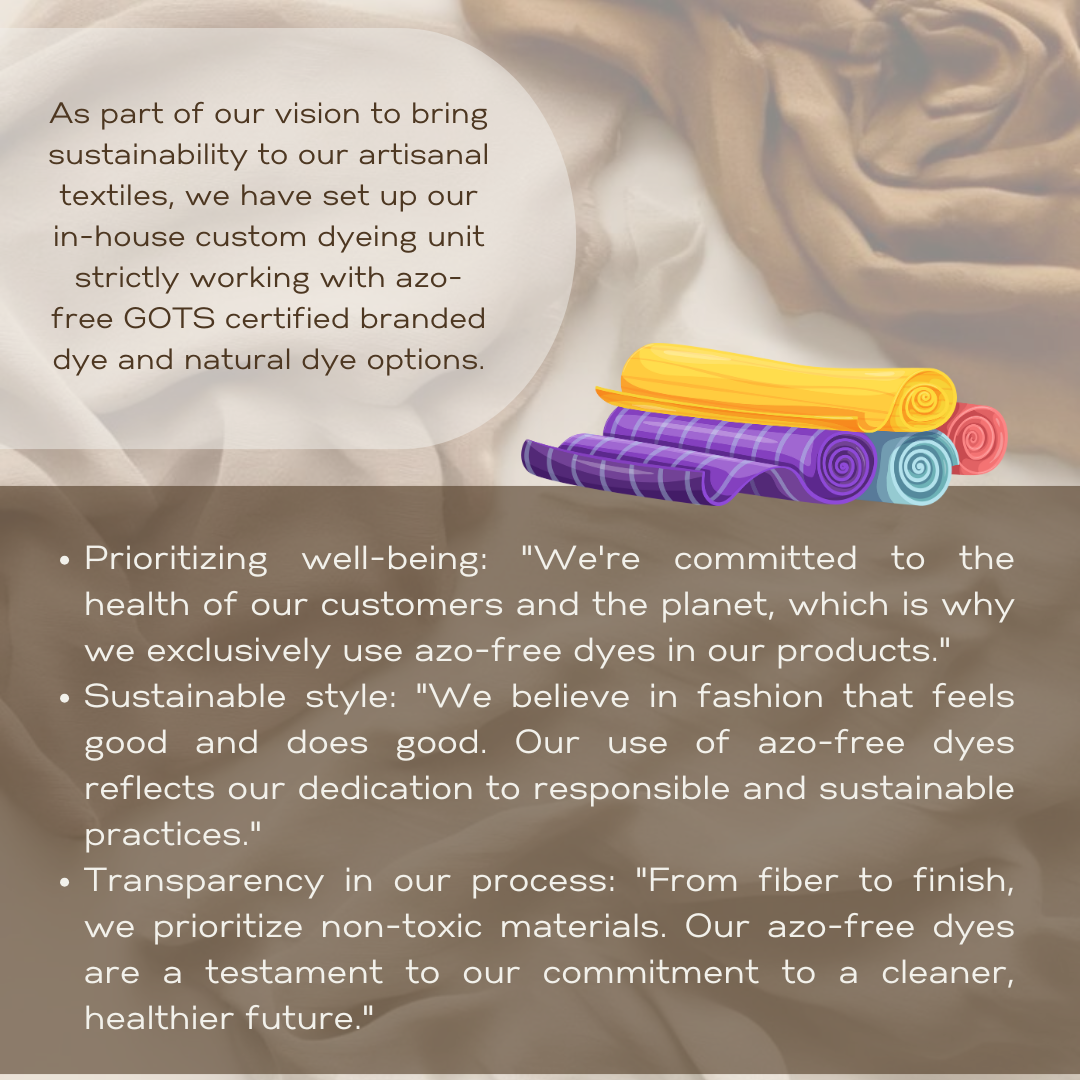

Processing: We are using a range of sustainable practices in our processing processes, including using 100% natural materials and azo-free dyes or 22 shades of natural vegetable dyes.

Weaving: Anuprerna works with handloom weavers from rural parts of West Bengal, supporting traditional crafts and local communities. The Handspinning & handlooms do not require fuel or electricity, further reducing the environmental impact of the weaving process.

Quality Checking: Anuprerna Artisan Alliance has strict quality control processes in place to ensure that all of its products meet the highest standards. Through continuous training & advice, we are able to reduce the rejection rate to below 5% on all our existing artisanal crafts.

Packaging: Anuprerna Artisan Alliance is committed to minimizing waste and using eco-friendly packaging materials whenever possible. For this reason, we also repurpose any deadstock fabrics for packaging which then can be further repurposed by our customers.

ARTISANAL BEHIND THE SCENES

MAKERS HIGHLIGHT

Suchita Guin is an artisan working in the Handwoven Linen Cluster of Purba Burdwan, West Bengal where she lives with a family of 3. Her role in the cluster includes the winding of the linen yarn.

Dilip Pal is a skilled Jamdani artisan from Chanduli village in Purbo Bardhaman district, where he lives with a family of 5.

ARTISANAL INSIGHT

Kalpana Guin is also working in the Handwoven Linen Cluster of Purba Burdwan, West Bengal where she lives with a family of 3. She weaves Linen fabric on the handloom and specializes in creating check patterns.

Rabi Dutta from Kinnahar village in Birbhum district. 60 years old, he lives with a family of 4.

He specializes in handweaving check patterns with fine yarns.

continuous impact improvement areas

How does the brand maintain fair trade practices consistently?

arrow_drop_downOur trade practices aim to empower artisans, fostering a sustainable environment that supports their education, family health, and motivates future generations to carry on these art forms.

How does the brand continuously improve working conditions for its workforce?

arrow_drop_downOur setup is primarily a family-oriented, home-worker economy where men weave, and women are typically involved in pre-weaving activities. We ensure fair wages, commensurate with those in respected professions, for everyone involved.

How does the brand improve ethical sourcing and supply chain transparency?

arrow_drop_downWith relationships spanning over 30+ years, we collaborate closely with over 300+ weavers in rural Bengal, India. Together, we craft ethical, sustainable, and exquisite handwoven textiles, honoring Bengal's indigenous weaves, traditions, and techniques.

How does the brand consistently integrate organic and environment-friendly materials for sustainability?

arrow_drop_downWe cater to customer requests by using organic cotton fiber and highlight the use of organic khadi along with azo-free organic dyes. These materials boast zero carbon footprint, being both eco-friendly and skin-friendly. In terms of environmentally friendly materials beyond organics, our focus is on fibers entirely handspun and handwoven. Additionally, we champion indigenous techniques like Jamdani, known for their benign impact on the environment.

How does the brand maintain its commitment to being animal-friendly in its products?

arrow_drop_downThe majority of our products involve handspun natural fibers like cotton and linen. Additionally, we use wild silk fabric, also known as peace silk or ahimsa silk, which is produced without harming the pupae inside the cocoons, ensuring no sacrifice of animal life.

What steps is the brand taking to continually enhance both energy and water efficiency in its operations?

arrow_drop_downOur products embrace artisanal crafts with handloom and handprinted techniques, requiring minimal energy—unlike mechanized industries that use 132 tons of coal yearly for fabric weaving, whereas we use none. Furthermore, by prioritizing natural fabric forms, we reduce water consumption, limiting dyeing processes that typically waste water. Our use of azo-free dyes minimizes chemicals and drastically cuts down water wastage in the environment.

How is the brand minimizing pollution through ongoing improvements in chemical management?

arrow_drop_downIn our chemical management, the dyeing stage is the primary process involving chemicals. While we currently use low-impact dyes, our focus is on establishing a wastewater management system. Additionally, we're exploring alternative natural dye processes for sustainability. As for pollution reduction, our textiles' entire lifecycle, from fiber procurement to hand spinning, yarn-making, and hand weaving, minimizes environmental impact significantly.

How is the brand continuously improving recycling and waste reduction efforts?

arrow_drop_downOur work with textiles naturally leads to minimal wastage. Regarding our use of low-impact dyes, we're actively developing a wastewater management system. Additionally, we've initiated exploration into alternative natural dyeing processes.

How does the brand ensure a sustainable business model for lasting impact?

arrow_drop_downOur primary crafts involve handspun and handwoven khadi, as well as the Jamdani technique. These methods significantly benefit the weaving community and the environment by creating jobs, empowering artisans, conserving water, and reducing carbon footprint.

More Blogs

empowering artisans, transforming lives: impact report 2024

2022 anuprerna impact report

about the founder

about the brand

about the platform

about anuprerna studio