Piece Dyed Fabrics

In the world of textile design, color is more than aesthetics—it’s an identity. And when it comes to delivering both creative control and heritage craftsmanship, piece dyed fabrics stand out as the ideal solution.

At Anuprerna, we combine Bengal’s weaving traditions with modern customization through this powerful piece dye technique, enabling designers and brands to work sustainably without compromising on vision.

Origin & Heritage of Piece Dyeing

The Industrial Revolution in the 18th and 19th centuries brought significant advancements to the textile industry. While piece dyeing as a technique is widely used globally, its integration with artisan handwoven textiles is what gives it special meaning in Indian textile traditions.

In Artisanal Village, where Anuprerna’s weaving clusters operate, the process of fabric dyeing post-weave aligns perfectly with slow, responsible, and modular production systems.

By offering piece dyed handlooms, Anuprerna supports:

- Efficient artisan scheduling

- Color flexibility for designers

- Lower environmental impact by reducing leftover dyed inventory

What is Piece Dyed Fabric?

Piece dyed fabric refers to fabric that is dyed after it has been woven. The textile starts out as "greige" or undyed fabric—often handwoven—and is later colored in its finished state.

This method offers design flexibility, precise color matching, and reduced waste, making it ideal for both bespoke creations and small-batch production.

At Anuprerna, we weave a wide variety of greige fabrics using handspun natural yarns—from khadi cotton to silk blends—which are then dyed in-house using either AZO-free certified dyes or natural vegetable dyes depending on your preferences and sustainability goals.

Piece Dyed Process Video

Process

Piece dyeing is a textile dyeing process where the fabric, typically in the form of large rolls or bolts, is dyed as a whole after it has been woven or knitted. This is in contrast to yarn dyeing or fiber dyeing, where the individual yarns or fibers are dyed before they are woven or knitted into fabric. Piece dyeing is a common method used in the textile industry to color a large quantity of fabric in a uniform manner.

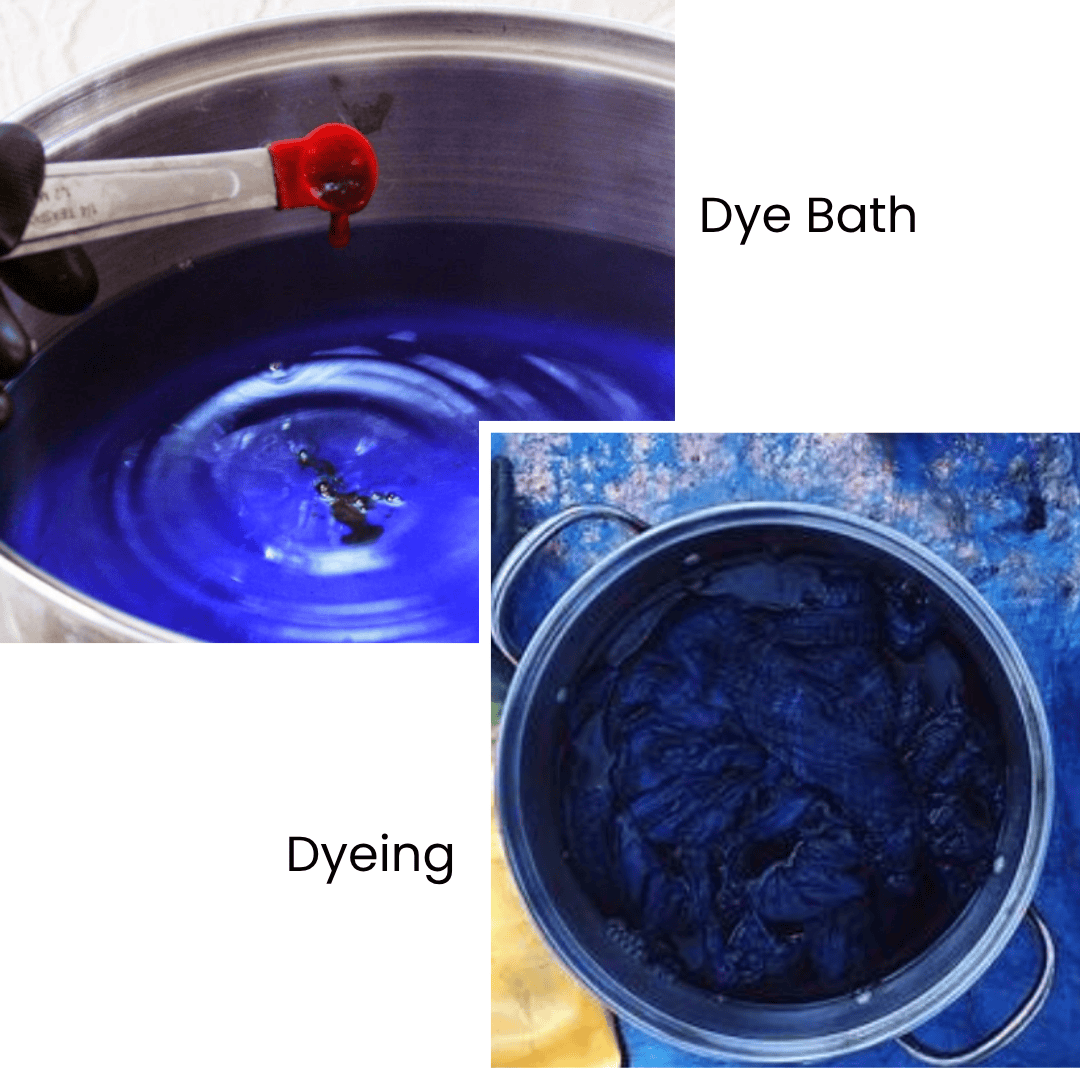

Dye bath preparation and Dying

Dye bath preparation: A dye bath is prepared with the chosen dye or colorant.

The dye bath may also contain other chemicals or auxiliaries to enhance dye uptake, fixation, and colorfastness.

Dyeing: The prepared fabric is immersed or passed through the dye bath. The fabric absorbs the dye, resulting in the desired coloration.

The duration of immersion and the temperature of the dye bath are carefully controlled to achieve consistent and even dyeing.

Piece dyeing process

The piece dyeing process is a textile coloring technique where the fabric, typically in its final, fully constructed form, is dyed as a whole piece.

This method is in contrast to yarn or fiber dyeing, where the individual threads are colored before being woven or knitted into fabric.

The piece dyeing process is commonly used for solid colors and allows for efficient and uniform coloring of the entire fabric piece.

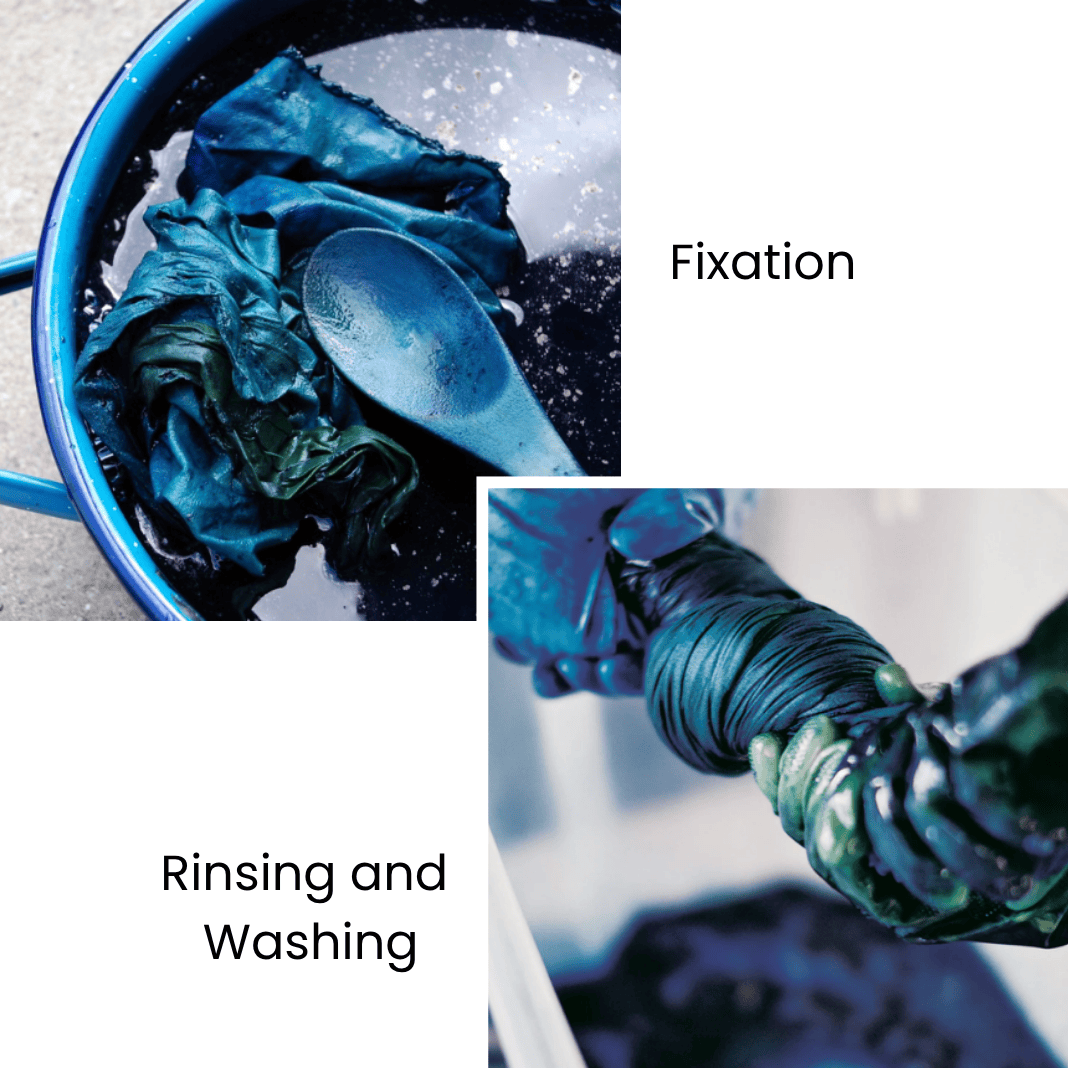

Fixation, Rinsing and Washing

Fixation : After dyeing, the fabric is often subjected to a fixation process.

This step involves treating the fabric with chemicals or heat to ensure that the dye molecules are permanently bonded to the fabric fibers, improving colorfastness.

Rinsing and Washing : The dyed fabric is thoroughly rinsed and washed to remove excess dye, chemicals, and any impurities.

This step is crucial for achieving the desired color and ensuring that the fabric meets quality standards.

Drying

The fabric is dried to complete the dyeing process. Depending on the fabric type and the intended application, drying methods may include air drying, heat drying, or a combination of both.

Benefits of Piece Dyed Fabrics

- Color Customization: You can choose your exact shade based on season, trend, or mood board—even post-weaving.

- Inventory Efficiency: Brands can stock one base fabric and dye it on demand—perfect for limited runs.

- Uniform Coloration: Advanced fabric dyeing methods ensure even and lasting color across the full width of the dyed fabric.

- Versatile Application: Works across cotton, linen, silk, and dyed yarn fabric bases.

Special Features of Anuprerna's Piece Dyed Fabrics

- Handwoven Base Textiles: Unlike factory-made alternatives, our base fabrics are made on handlooms by artisans—each piece carries depth, texture, and story

- AZO-Free & Natural Dyes: We offer ISO & GOTS certified dye options, including shades derived from indigo, turmeric, madder, and more.

- Custom Orders & Swatches Available: Designers can test multiple shades or weights before placing a bulk preorder.

- Scalable for Small to Mid Batches: Ideal for conscious brands and capsule collections.

Different Types of RFD Fabrics

RFD Cotton Fabric:

Cotton is a popular choice for RFD fabrics due to its natural fiber properties.

RFD Linen Fabric:

RFD linen fabrics are often chosen for their crisp and cool feel, making them suitable for summer clothing and home furnishings.

RFD Hemp :

RFD hemp fabric is carefully prepared and primed for the dyeing process, offering you the freedom to customize it with your chosen colors and designs.

RFD Khadi Fabric :

Specially prepared for the dyeing process, RFD Khadi fabrics provide a high-quality and versatile foundation for creating personalized, vibrant designs.

Explore More about the Types

RFD Silk Fabric:

RFD silk fabrics are chosen for high-end clothing items, lingerie, and accessories.

RFD Blended Fabrics:

Blended RFD fabrics combine different types of fibers to achieve specific properties.

RFD Denim Fabric:

Denim RFD fabrics are used in the production of jeans, jackets, and other durable clothing items.

RDF Banana fabric :

RFD banana fabric is derived from banana plant fibers, combining the strength of this natural resource with the versatility of customization.

Fabric Care Tips

Proper care enhances the longevity and appearance of your dyed clothes:

- Gentle hand wash or machine wash (cold)

- Use mild, pH-neutral detergent to preserve dye vibrancy

- Dry in shade to avoid fading

- For naturally dyeing fabric, avoid strong soaps or bleach

Bonus tip: Pre-soak naturally dyed fabric in salt water before first use to help fix color naturally.

Conclusion

In a time where fast fashion favors volume over value, piece dyed fabrics offer precision, sustainability, and individuality. With this method, you don’t just choose a fabric—you craft a palette, one piece at a time.

At Anuprerna, our piece dyed handwoven fabrics help you build thoughtful collections that carry the soul of Bengal and the spirit of modern design.

frequently asked questions

What is the difference between yarn dyeing and piece dyeing?

arrow_drop_downYarn dyeing involves dyeing the yarns before they are woven or knitted into fabric, resulting in colored yarns and often creating patterns or stripes. Piece dyeing, on the other hand, involves dyeing the fabric after it has been woven or knitted into its final form, resulting in uniformly colored fabric.

What are the advantages of piece dyeing?

arrow_drop_downAdvantages of piece dyeing include cost-effectiveness for large fabric quantities, consistent color throughout the fabric, flexibility in color choices, efficient processes, and reduced waste by dyeing only the amount of fabric needed for the final product, minimizing excess dyeing of unused yarns.

How is piece dyeing done?

arrow_drop_downIn piece dyeing, fabric is immersed in a dye bath or subjected to dye application methods such as spraying or padding. The fabric absorbs the dye, resulting in uniform coloration. The dyed fabric is then rinsed, washed, and dried before further processing or use.

What is piece dyeing?

arrow_drop_downPiece dyeing is a textile dyeing process where the fabric is dyed after it has been woven or knitted into its final form, typically in a large continuous piece. This allows the entire piece of fabric to be dyed uniformly in one color or multiple colors before being cut and sewn into finished garments or products. Piece dyeing is commonly used for fabrics like cotton, polyester, and blends.

More Stories

yarn dyed khadi cotton

handwoven merino wool

handwoven linen

patachittra wall art

eri peace silk

naturally dyed block printing